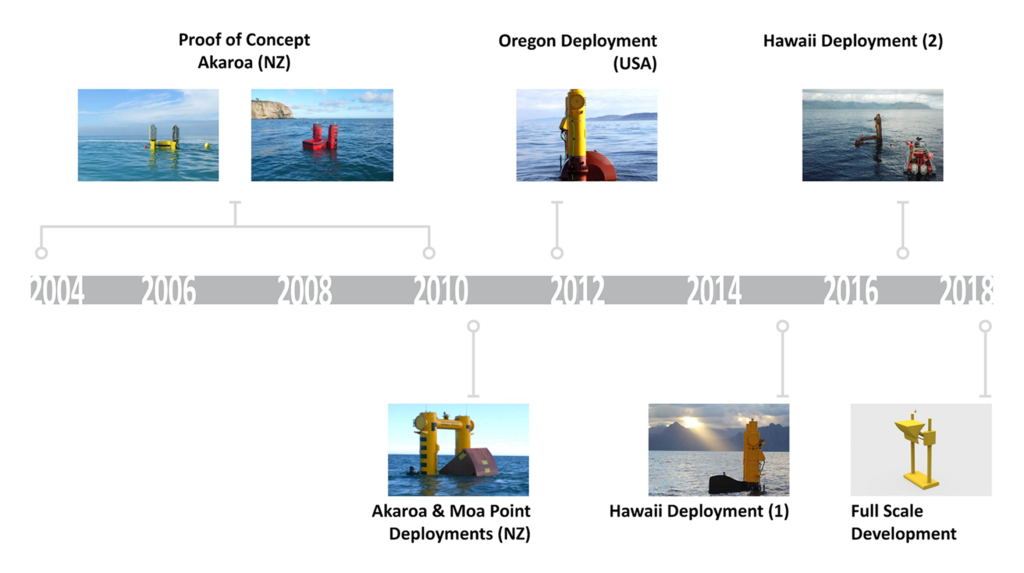

Since concept and initial development in 2006, the Azura technology has advanced from initial concept (TRL 1) and micro-scale modeling stage (TRL 3) to open ocean testing of large scale prototypes (TRL 5/6). Under the R&D program implemented in New Zealand, three prototypes were deployed for open-ocean testing, including a TRL 5/6 prototype deployed near Christchurch, NZ.

The Oregon prototype was fabricated, deployed and tested in 2012 in the open ocean at the NNMREC wave energy test site off the coast of Newport, OR. This marked the first successful deployment of a TRL 5/6 wave energy device in Oregon and first device to be connected to NNMREC’s instrumentation buoy, the Ocean Sentinel. More than 30 million pieces of data were collected which were analyzed and formed the basis of the TRL 7/8 or first commercial scale design. Learn more about the Oregon Pilot project.

The Oregon prototype was fabricated, deployed and tested in 2012 in the open ocean at the NNMREC wave energy test site off the coast of Newport, OR. This marked the first successful deployment of a TRL 5/6 wave energy device in Oregon and first device to be connected to NNMREC’s instrumentation buoy, the Ocean Sentinel. More than 30 million pieces of data were collected which were analyzed and formed the basis of the TRL 7/8 or first commercial scale design. Learn more about the Oregon Pilot project.

Running concurrently the Moa Point (4 weeks) and Oregon (6 weeks)demonstrations projects tested different float configurations and sea states to finalise the design, prior to long term (18 month) grid connection trials at the US Navy’s Wave Energy Test Site (WETS) in Hawaii.

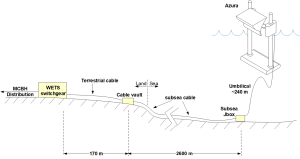

In September 2012, the project was selected by the DOE and the US Navy via a competitive process to  modify and redeploy the prototype at the Navy’s Wave Energy Test Site (“WETS”) located at the Marine Corps Base Hawai’i (“MCBH”). The Navy had been evaluating Ocean Power Technologies’ (“OPT”) PowerBuoy technology at the WETS site since 2003. However, the OPT device has been removed and the Navy is now working with the Azura team to evaluate Azura as a cost-effective and secure means to supply power to their bases.

modify and redeploy the prototype at the Navy’s Wave Energy Test Site (“WETS”) located at the Marine Corps Base Hawai’i (“MCBH”). The Navy had been evaluating Ocean Power Technologies’ (“OPT”) PowerBuoy technology at the WETS site since 2003. However, the OPT device has been removed and the Navy is now working with the Azura team to evaluate Azura as a cost-effective and secure means to supply power to their bases.

Azura was initially deplpoyed at WETS in June 2015 where Azura was successfully connected to Hawaii’s power grid and became the first grid connected wave energy device in North America. During this initial 18-month deployment Azura achieved 98% availability and continued to produce with no damage through a 7.5-meter wave height hurricane. Independent third party validation and monitoring was undertaken by the University of Hawaii to ensure high level specialised analysis to assist in system refinement and optimisation.

Key outcomes from WETS deployment #1

- Device modified after analysis and review of data from initial deployment:

- New float configuration

- Introduction of heave plate

- Further 6-month deployment. (Deployment#2)

- Data validated with WECSim model for development of commercial scale design.